Understanding Titanium Electrodes: Manufacturing, Advantages, and Applications | YASA ET

- kunyapak

- Dec 18, 2025

- 4 min read

Updated: Dec 21, 2025

Content

1. Introduction: Why Titanium Electrodes Matter

Titanium electrodes commonly known as DSA® (Dimensionally Stable Anodes) are high-performance, corrosion-resistant, and long-lasting electrode materials widely used in modern electrochemical industries.

With excellent catalytic activity, stable geometry, and flexible manufacturing options, titanium electrodes have become indispensable in:

Electrocoagulation (EC)

Electro-oxidation (EO)

Metal recovery and electroplating

Disinfectant generation

Zero Liquid Discharge (ZLD) wastewater treatment

In advanced systems such as PREDEST® EC/EO, titanium electrodes play a critical role in ensuring high efficiency, stable operation, and long service life under harsh industrial conditions.

2. What Are Titanium Electrodes?

Titanium electrodes are insoluble anodes manufactured using high-purity titanium (TA1 or TA2) as the substrate.

Their surfaces are coated with precious metal oxides, including:

Iridium oxide (IrO₂)

Ruthenium oxide (RuO₂)

Platinum (Pt)

Mixed metal oxide (MMO) formulations

These coatings form a durable, conductive, and corrosion-resistant electrochemical interface, delivering significantly better performance than traditional graphite or lead-based electrodes.

Titanium electrodes are also commonly referred to as:

Titanium anodes

Titanium-based insoluble anodes

DSA® (Dimensionally Stable Anodes)

3. Key Advantages of Titanium Electrodes

Titanium electrodes provide multiple technical and economic advantages:

Excellent oxygen and chlorine evolution performance

High catalytic activity at low overpotential

Capability to operate at higher current densities

Stable electrode spacing for uniform electrolysis

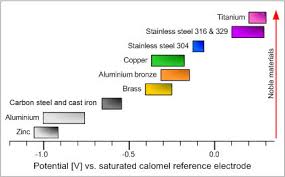

Outstanding corrosion resistance and long service life

No sludge shedding or contamination

Flexible geometries: plates, mesh, porous titanium, tubes, rods, or complex shapes

High-precision manufacturing for system integration

Titanium substrates can be recoated and reused, reducing lifecycle cost

4. Titanium Electrode Manufacturing Process

The production of titanium electrodes involves precise and controlled steps to ensure coating adhesion, electrode stability, and catalytic performance.

4.1 Titanium Substrate Selection

Material: TA1 or TA2 titanium

Forms: plates, porous titanium, mesh, tubes, rods, or custom designs

4.2 Cutting and Forming

Titanium is cut and formed according to customer specifications and system design requirements.

4.3 Sandblasting

Purposes:

Remove oxide layers and surface contamination

Create macro-roughness to enhance coating adhesion

Increase effective surface area and reduce real current density

Typical roughness: Ra 2–15 μm, depending on application.

5. Titanium Substrate & Coating Materials

5.1 Straightening

Sandblasting may cause deformation, corrected by:

Thermal annealing

Mechanical straightening

5.2 Degreasing

Oil and residue removal improves acid etching uniformity and coating adhesion.

5.3 Acid Etching

Functions:

Remove residual oxide film

Create micro-roughness for coating bonding

Common etchants:

Oxalic acid (milder, but produces high-COD wastewater)

Hydrochloric or sulfuric acid (stronger, no COD contribution)

6. Surface Treatment & Thermal Processing

6.1 Coating Application

Precious metal oxide coatings are applied by:

Brushing

Rolling

Spraying

Key requirements:

Uniform coating

No pooling, leakage, or drips

6.2 Low-Temperature Drying

Drying at 100–200 °C for ~10 minutes removes solvents prior to sintering.

6.3 High-Temperature Sintering

Electrodes are sintered at 450–550 °C for 10–20 minutes to bond the coating to the titanium substrate.

6.4 Multiple Coating Cycles

The sequence (Coating → Drying → Sintering) is repeated until the target coating thickness is achieved. Final sintering typically lasts around 1 hour.

7. Quality Control & Service Life

Finished titanium electrodes undergo comprehensive quality testing, including:

Coating uniformity inspection

Adhesion strength testing

Oxygen evolution potential

Chlorine evolution potential

Flatness and dimensional accuracy

Proper manufacturing and testing ensure long service life and stable electrochemical performance.

8. Applications of Titanium Electrodes

Titanium electrodes are widely used in high-performance electrochemical processes:

Electrocoagulation (EC) and Electro-Oxidation (EO)

Industrial wastewater treatment & ZLD systems

Electroplating and metal finishing

PCB manufacturing

Copper foil and aluminum foil production

Chlorine and sodium hypochlorite generation

Cathodic protection systems

Electrolytic metal recovery

Energy storage and hydrogen production

They are core components in PREDEST® EC/EO systems, ensuring efficiency, durability, and operational stability.

9. Special Notes & Design Considerations

Precious metal oxides are costly; optimizing metal loading while maintaining performance is a key research focus.

Even within the same coating family (Ir-Ta, Ru-Ir, Pt-based), formulations vary significantly depending on electrolyte composition and operating conditions.

Proper electrode selection is critical for performance, lifespan, and operating cost.

10. Conclusion & References

Conclusion

Titanium electrodes represent the most advanced class of industrial anodes, offering unmatched durability, catalytic efficiency, and adaptability.

Their importance in wastewater treatment, ZLD systems, electrochemical manufacturing, and environmental engineering continues to grow, supported by advanced manufacturing techniques and continuous innovation.

For more information on titanium electrodes and PREDEST® EC/EO solutions, visit www.predest-ec.com.

References

Trasatti, S. Electrodes of Conductive Metallic Oxides. Elsevier, 1980.

Beer, H. B. “The invention and industrial development of DSA®.” Journal of the Electrochemical Society, 1980.

Comninellis, C. “Electrocatalysis in anodic oxidation of organics.” Electrochimica Acta, 1994.

Martínez-Huitle, C. A., & Ferro, S. “Electrochemical oxidation of organic pollutants.” Chemical Society Reviews, 2006.

Chen, G. “Electrochemical technologies in wastewater treatment.” Separation and Purification Technology, 2004.

Mollah, M. Y. A. et al. “Electrocoagulation for the treatment of wastewater.” Journal of Hazardous Materials, 2001.

Sirés, I., & Brillas, E. “Electrochemical advanced oxidation processes.” Environmental Science & Technology, 2012.

ASTM B348 – Standard Specification for Titanium and Titanium Alloy Bars and Billets.

Comments