EC Lab Test Update — Manure Wastewater

- kunyapak

- Aug 15, 2025

- 4 min read

What you’re looking at (and why it matters)

Manure wastewater is a tough stream: highly colloidal, rich in organics and nutrients, and constantly fluctuating. As a pretreatment, Electrocoagulation (EC) is designed to “knock the edge off” quickly. By passing direct current across iron or aluminum plates, the anode releases metal ions that hydrolyze into in-situ metal hydroxide coagulants; microbubbles formed at the cathode help lift the newly formed flocs. In minutes, unstable colloids agglomerate, phosphorus binds to the metal hydroxide matrix, and a floating or settleable blanket separates from clarified water (1)(3).

A dense, foam-like floc layer forms at the liquid surface while Fe/Al electrodes are energized. This is electro-flotation working together with electrocoagulation to concentrate solids and carry them to the top.

Left: raw influent, Middle: heavy floc formation and phase separation, Right: clarified water after solid–liquid separation. One frame tells the story of EC as a fast, robust pretreatment.

These visuals emphasize three practical truths you can carry forward.

First, clarity improves fast minutes, not hours because charge neutralization and sweep flocculation happen inside the tank (1).

Second, phosphate gets removed with the floc, as orthophosphate adsorbs or co-precipitates with Fe/Al hydroxides (4).

Third, performance tracks current density × time; pushing harder generally improves removal, but you must balance it against power use and electrode consumption (1)(3).

Why EC is a strong fit for manure wastewater

Compared with many industrial effluents, manure wastewater contains a stubborn blend of fines, colloids, oils/organics and high nutrients.

EC addresses the front-end pain points:

Colloids and turbidity: in-situ hydroxide flocs neutralize charges and sweep out suspended solids rapidly, easing the burden on downstream clarification, membranes or evaporation (1)(3).

Phosphorus control: Fe/Al hydroxides strongly bind phosphate; literature consistently reports very high orthophosphate removal when current density and residence time are adequate (4).

A platform for polishing: if you also need color/odor control or to reduce refractory organics and ammoniacal nitrogen, EC sets the stage for a polishing step such as electrochemical oxidation (EO) or ammonia stripping (5).

In short, EC = clarity fast + P capture now, so the rest of the treatment train can run smoother and more stable.

Making it “full-process”: nitrogen, reuse and resource recovery

EC alone is not the finisher for ammonia in high-strength manure wastewater. If your permit or reuse target includes N, plug in one of these routes:

EO polishing (e.g., Ti₄O₇ or BDD anodes): strong oxidants generated at the anode attack refractory organics and convert reduced nitrogen species; there is a real-stream case study on swine wastewater with Ti₄O₇ that demonstrates this integration (5).

Air/steam stripping: a simple, cost-effective option where ammonia load is dominant and you want to recover or neutralize it downstream.

Don’t discard phosphorus value. The floc/sludge from EC can be a phosphorus source. Converting it to struvite (MgNH₄PO₄·6H₂O) closes the loop and reduces operating cost; studies on swine wastewater show high-quality precipitates and strong recovery potential under controlled conditions (2).

From bench to field: a practical roadmap

Set the KPI. Define whether you’re aiming for discharge, reuse or ZLD; list must-hit parameters (clarity, P, N, color/odor).

Run a short design-of-experiments. Step current density and runtime methodically; keep plate spacing and mixing shear consistent; log everything as above.

Engineer the solids path. EC → clarifier or DAF → thickening/dewatering, sized for the observed blanket rate and sludge characteristics.

Add the finishers only where needed. For N or refractory organics, choose EO or stripping; for water reuse/ZLD, connect membranes or evaporation/crystallization; for P recovery, add a struvite stage (2)(5).

Decide with evidence. Even without publishing numbers, your photos, logs and operating envelopes tell procurement/ESG teams what CAPEX/OPEX will look like and how the plant will run day-to-day.

Yasa solutions you can order today

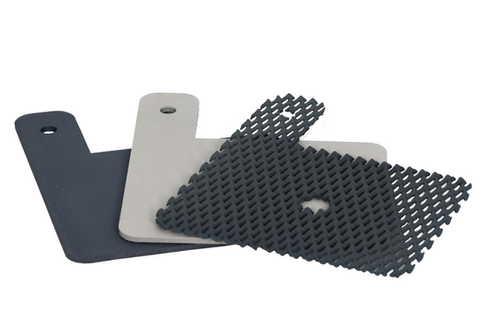

EC/EO Lab Kits (ready to run) : Transparent recirculating cell, pump and flow metering, DC power supply, Fe/Al plates, hoses/fittings and quick-start guidance. Perfect for parameter finding, stakeholder demos and building your operating envelope.

Electrodes & upgrades : Fe, Al, Ti, Ti-RuIr (DSA) and BDD/Ti₄O₇ options for EO polishing; cut-to-size plates and custom spacing available.

Modular EC–DAF Pilot : Bridge from bench to site capture real energy use, electrode consumption, sludge behavior and post-EC water quality so you can design the full train (EO/membranes/evaporation/struvite) with confidence.

Order / Quote: info@yasa.ltd

S-EC/EO TEST KIT -1A

Buy Now

S-EC/EO TEST KIT - 5A

Buy Now

S-EC/EO TEST KIT -10A

Buy Now

EO Plates for YASA ET Test Kit

Buy Now

Comments